-

Address

Address -

Mail Us Oninfo@mamtatools.in

Mail Us Oninfo@mamtatools.in

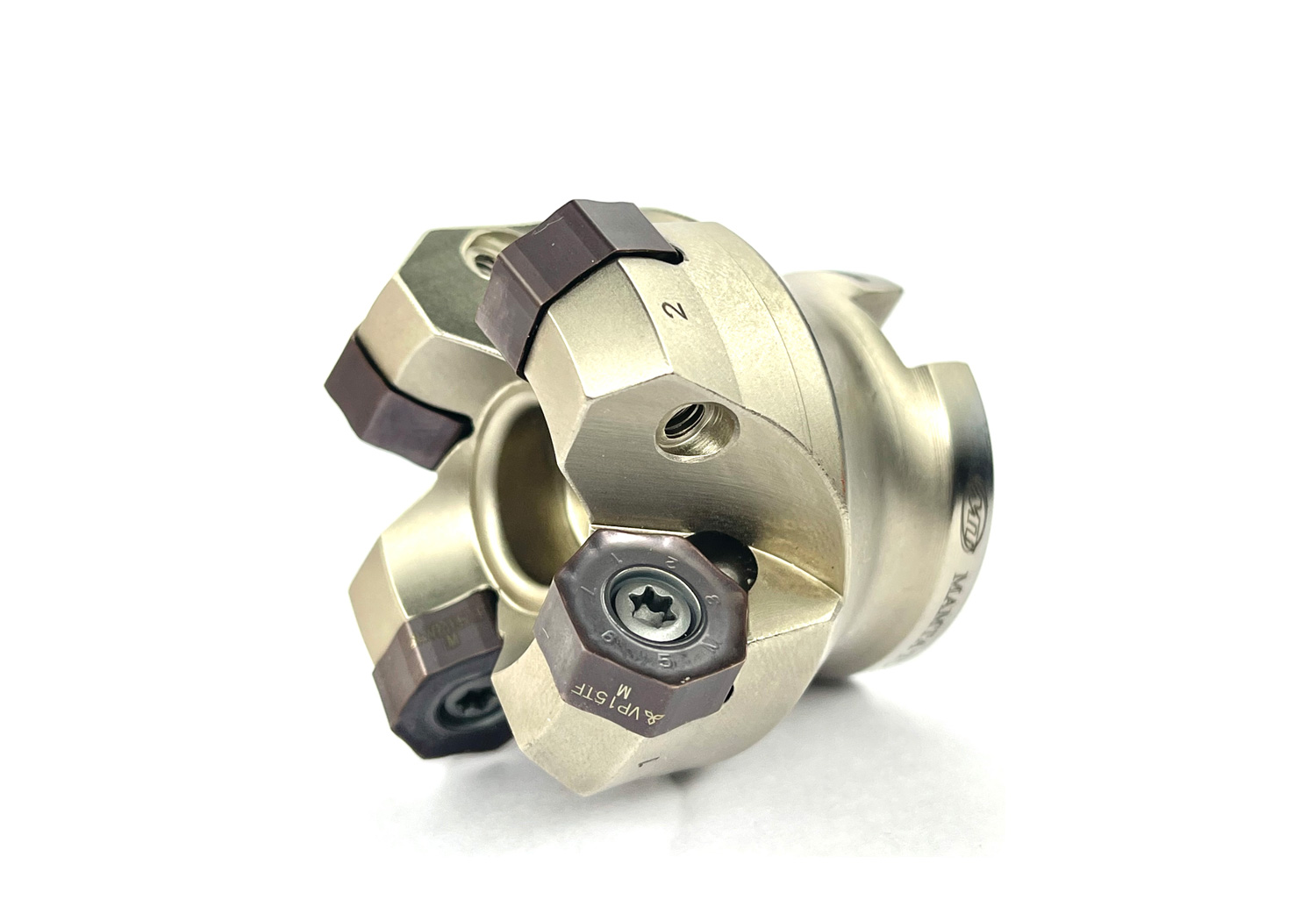

We are Manufacturer, Supplier, Trader, Exporter of Face Mill Cutters, Face Milling Cutters, Milling Cutters, Face Milling Tools, Cutting Tools, Industrial Cutters, Indexable End Mill Cutters, Profile Milling Cutters, Modular Shank Cutters, Side Milling Cutters and our setup is situated in Talawade, Pune, Maharashtra, India.

As an Industrial Cutter Manufacturer, we understand the importance of precision and durability when it comes to machining operations. That's why we're proud to offer a wide range of cutting tools designed to meet the demands of modern manufacturing. Whether you're looking for indexable end mill cutters, profile milling cutters, modular shank cutters, or any other type of cutting tool, we've got you covered.

Milling cutters are essential cutting tools used in the machining process to remove material from a workpiece. There are different types of milling cutters, including face milling cutters and side milling cutters. These cutters have unique features that make them suitable for specific milling operations. In this article, we will discuss face milling cutters and side milling cutters in detail.

Face milling cutters are essential tools in the realm of machining, specifically designed for the efficient and precise removal of material from a workpiece's surface. These cutting tools, commonly known as face mill cutters, feature multiple cutting edges on their periphery, facilitating rapid and uniform material removal during the machining process. The design of face milling cutters allows them to create flat surfaces, intricate patterns, or precise contours on a workpiece. These cutters are widely employed in various industries, including automotive, aerospace, and manufacturing, for tasks such as facing, squaring, and smoothing surfaces. Their versatility makes them ideal for a range of applications, from roughing to finishing operations. Face milling cutters can be utilized on a variety of materials, including metals, plastics, and composites, showcasing their adaptability in diverse machining scenarios. Overall, these cutting tools play a crucial role in achieving high-quality surface finishes and meeting tight tolerances in modern machining processes

- Design for high performance face milling

- Simple handling in setting and insert replacement

- Capable of both high metal removal.

- Optimized insert geometries and grades for machining of steel, stainless steel, cast iron, and non-ferrous- excellent for mixed production.